Developments / New technologies

POLLUTION-FREE SILICATE BINDERS TO PRODUCE CONSTRUCTION MATERIALS

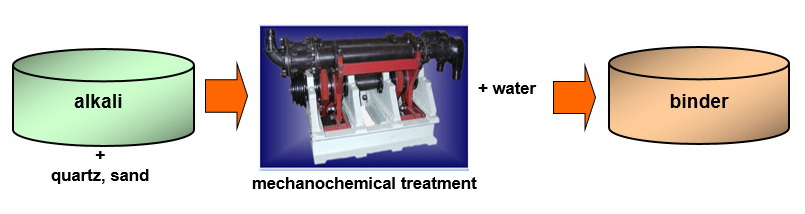

The processes of silicate binding material production with the use of mechanochemical methods have been developed. A silicate binding material is sodium liquid glass with a hardener – pollution-free mineral natural additives. Low-temperature non-autoclave methods of sodium liquid glass production with the use of a wide range of silicate-containing materials have been developed.MECHANOCHEMICAL SYNTHESIS OF BINDING MATERIAL FROM SAND

ADVANTAGES:

- tearing strength of binder – 50 MPa

- crushing strength of products – more than 200 MPa

- water-insoluble after firing at 150 0C

- don’t swell up at heating

APPLICATION OF SILICATE BINDER FOR THE PRODUCTION OF CONSTRUCTION MATERIALS

Fire-resistant, pollution-free water-resistant wood particle board from sawdust, chip, bark, rice husk etc.

Advantages:- changing of phenol-formaldehyde resin;

- usage of waste of wood-working industry and agriculture

Expanded clay from industrial and domestic waste

Advantages:- changing from mineral wool to a cheaper and more durable material;

- usage of production waste

Decorative building plates (“artificial granite”) produced with the use of silicate binder

Advantages:- increased hardness;

- great fire-resistance;

- absence of dangerous organic binders

RF patents have been taken out.

Contact us:

Institute of Solid State Chemistry and Mechanochemistry SB RAS

Kutateladze str., 18 Novosibirsk, 630128 Russia

Phone: +7(383)332-53-44

Fax: +7(383)332-28-47

E-mail: root@solid.nsc.ru