Science / The most important results

2014

Development of the methods for the controllable synthesis of nanoparticles of metals and alloys for use in additive technologies.

Authors: Yu.M. Yukhin, A.I. Titkov, N.Z. Lyakhov

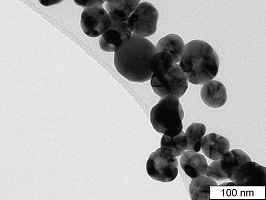

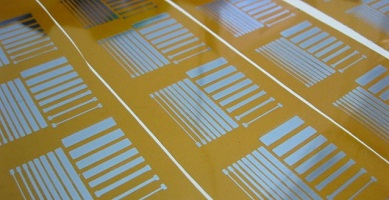

The extraction polyol method was developed to synthesize surface-modified nanoparticles of metals (silver, copper, nickel, bismuth and their alloys). This method allows obtaining metal powders with the average particle size from 10 nm to 10 m for use in additive technologies. On the basis of this method, electroconductive ink for jet printing to form electroconductive elements and coatings on flat substrates was developed for the purpose of making functional materials and devices in electronics, instrument engineering, aviation, space-system engineering and other areas. Metal nanoparticles and ink based on them may find application in photovoltaics for making electroconductive contacts when manufacturing solar batteries, OLED displays and light sources, chemical sensors, for prototyping printed circuit boards, for metal-plating ceramic ware, for making RFID antennas, electroconductive composite materials – pastes, glues, and polymers.

|

|

| Electron microscopic image of silver nanoparticles. | Jet printing with the ink based on silver nanoparticles. |

Development of the technology of mechanochemical manufacture of the preparations of soluble silicon from plant raw materials

Authors: O.I. Lomovsky, E.G. Trofimova, I.O. Lomovsky

A solid-phase mechanochemical reaction of silica from rice husk and gallocatechines (antioxidants) of green tea was carried out for the first time. As a result, preparations containing soluble biologically available silicon in the form of chelate complexes were obtained. On the basis of the solid-phase reaction, ecologically safe technology without using water and organic solvents was developed. According to this technology, the product is obtained in special mechanochemical activator mills within one operation. The preparation provides an increase in survivability of broilers in industrial poultry breeding. The preparation was tested in a series of poultry farms and entered the market in Russia and in Kazakhstan. The first licenses were sold to companies in Moscow (Limited Company “Osnova Rosta”) and in Novosibirsk (Limited Company “Mekhtsentr”).

|

The main unit of activator mill (the version in noise-suppressing case) for the production of 80 kg of powder product per hour. The power of the installation is sufficient to provide the addition of the preparation into fodder for 1 mln broilers.

|

Development of silicon carbide composite materials for the components of the hot channels of gas turbine engines

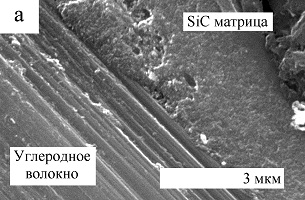

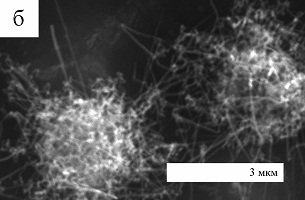

Authors: N.I. Baklanova, A.V. Utkin, N.Z. Lyakhov

The scientific foundations are developed for the technology of obtaining high-temperature composite materials composed of the silicon carbide matrix and reinforcing carbon fibers. Pre-ceramic polymers of original structure, manufactured in Russia, were used to form the silicon carbide matrix. These polymers give a high ceramic yield during heating. The use of new approaches to the formation of silicon carbide composites opens the possibility to obtain materials with improved thermomechanical properties.

|

|

Ceramic matrix composite composed of a silicon carbide matrix obtained from pre-ceramic polymer, and carbon fibers (left). Additional reinforcing of the composite is provided by filamentous crystals of silicon carbide formed from pre-ceramic polymers (right). |

|